Every boardroom faces the same expensive myth about data center equipment lifespan. Tech giants push a compelling narrative: replace your data center equipment every three to five years, or risk falling behind. Sound familiar?

This narrative thrives on fear. OEM warranties conveniently expire after three years, while sleek marketing campaigns showcase the latest innovations. The message is clear: upgrade or become obsolete.

Here’s what they don’t advertise: premature equipment replacement bleeds your budget dry. Early adopters often face configuration issues, testing problems, and deployment challenges. Even tech giants challenge this wasteful cycle. Microsoft recently extended their cloud server lifespan from four to six years. Their decision exposes a crucial industry truth.

Modern servers maintain competitive performance longer than ever. Moore’s Law has slowed, meaning today’s hardware nearly matches newer models in capability.

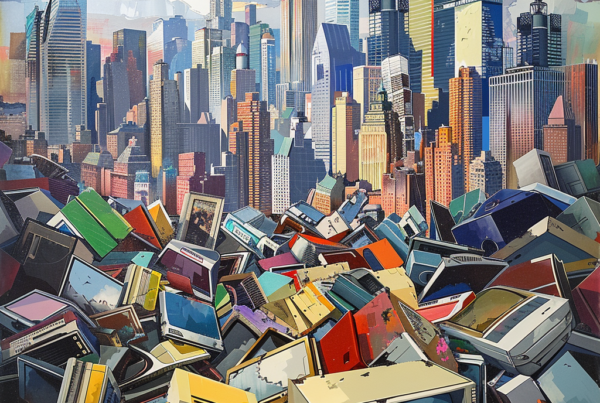

Yet organizations continue discarding viable equipment. They waste capital on unnecessary upgrades while functioning servers head to recycling centers and landfills. We’re burning money and resources chasing an artificial upgrade cycle. So what’s the real cost of believing our equipment expires before its time?

Table of Contents

- The Hidden Toll of Premature Data Center Equipment Replacement

- Maximizing Data Center Equipment Lifecycle

- The ROI of Extended Data Center Equipment Lifecycles

The Hidden Toll of Premature Data Center Equipment Replacement

Emergency repairs devastate budgets twice – first with rushed hardware costs, then with premium labor rates for immediate fixes. While third-party maintenance could save organizations 50-70% on support costs, many continue following this costly cycle of reactive spending.

These visible costs only scratch the surface of the financial impact. Behind every premature upgrade lies a cascade of hidden expenses: productivity losses during migrations, reduced system capacity during transitions, and disrupted customer-facing services. Meanwhile, organizations discover hundreds of thousands of dollars worth of perfectly usable servers sitting idle in data center corners.

Early adopters pay dearly for being first, discovering the most flaws in new equipment. Significant microcode updates plague the first two years of product lifespan, consuming precious IT resources with each fix.

System compatibility throws another wrench into operations as new equipment conflicts with existing infrastructure. Real-time monitoring shows existing systems maintain reliability far longer than expected, yet teams struggle to maintain performance while bridging technological gaps.

Fresh interfaces demand extensive staff training while documentation remains incomplete. Your experienced team becomes novices again, grappling with support channels that lack solutions for emerging problems.

Environmental Costs We Can No Longer Ignore

Manufacturing creates 24% of a data center’s carbon footprint before processing its first byte. This upfront environmental cost compounds with each premature replacement, creating a cycle of unnecessary energy consumption that efficiency gains rarely offset.

Operational use accounts for 76% of emissions, yet organizations routinely discard equipment while it still performs efficiently. As discarded hardware fills processing facilities, toxic materials like lead, mercury, and flame retardants leach into soil and groundwater. These facilities struggle to manage ever-increasing volumes of premature e-waste.

Industry leaders have already proven a better path exists. Google has resold over 44 million hardware components since 2015, while HPE processes three million units yearly with a 90% reuse rate. Their success demonstrates how extending equipment life aligns business growth with environmental responsibility.

Maximizing Data Center Equipment Lifecycle

The Truth About Modern Hardware Longevity

Today’s hardware tells a fundamentally different story than marketing suggests. Storage failure rates hover between 0.1-0.2% even after five years of continuous operation, debunking the myth of rapid deterioration.

This reliability stems from a crucial shift in computing evolution. Moore’s Law’s slowdown means performance gains between generations have plateaued, fundamentally changing the upgrade equation. Service Express’s analysis of over 500,000 devices proves equipment consistently delivers reliable service well beyond standard replacement cycles.

By leveraging this technology plateau, organizations maintain competitive performance while maximizing their investments. Instead of chasing marginal improvements, they can focus on optimizing their existing infrastructure through strategic maintenance and monitoring.

Revolutionary Maintenance Strategies

Condition-Based Maintenance Transforms Operations

Modern maintenance revolves around prevention rather than reaction. AI-driven algorithms continuously monitor performance metrics, analyzing patterns 24/7 to detect subtle changes that signal potential issues. These sophisticated systems transform raw data into actionable insights through real-time collection and analysis.

By generating component-specific alerts and detailed health scores, teams pinpoint exactly where and when to focus maintenance efforts. Machine learning algorithms predict potential failures weeks before they occur, enabling scheduled maintenance during planned downtime instead of emergency repairs.

Smart Component Management

Strategic component management starts with understanding each part’s lifecycle potential. While some components may need replacement, others—like high-value GPUs and networking equipment—often retain significant operational and market value well beyond standard lifecycles.

Regular performance monitoring validates these decisions through concrete data. Health analysis scores guide strategic choices about which components to upgrade, maintain, or continue operating at peak efficiency, eliminating guesswork from lifecycle planning.

Environmental Optimization

Sophisticated airflow management systems extend equipment life through precise control. Smart temperature monitoring and adjustment prevent component stress while optimizing performance. Regular equipment recalibration maintains peak efficiency levels throughout extended lifecycles.

These environmental controls work in concert with monitoring systems to create ideal operating conditions. This integrated approach maximizes hardware longevity while minimizing energy consumption and operational costs.

Strategic Equipment Redeployment

Internal Solutions and External Opportunities

Organizations can breathe new life into older data center hardware through strategic redeployment. Production servers often find perfect second careers powering development environments or handling backup operations.

Thin client implementations transform aging servers into powerful virtual desktop hosts. This approach maximizes resource utilization while providing flexible, scalable solutions for evolving business needs.

Externally, a thriving ecosystem of specialized vendors helps organizations capture residual value from older equipment. HPE’s success in processing three million units yearly with a 90% reuse rate demonstrates the scale of these opportunities.

Third-party maintenance specialists dramatically extend equipment usefulness while reducing support costs by 50-70% compared to OEM pricing. Additionally, vendors like Human-I-T offer certified refurbished equipment, thereby extending the life of used equipment donated to them by data centers. This combination of extended life and reduced costs creates compelling financial benefits and supports a data center’s ESG goals.

The impact of these strategic approaches extends far beyond immediate cost savings. By implementing these solutions, organizations unlock a new paradigm of sustainable IT operations that delivers remarkable results.

The ROI of Extended Data Center Equipment Lifecycles

Beyond Basic Cost Savings

Smart lifecycle management accelerates digital transformation budgets. Data centers that extend equipment life stand to save thousands to hundreds of thousands of dollars annually. Think about all that could be accomplished with that money back in your budget!

Strategic maintenance planning reduces total cost of ownership beyond support savings. And equipment familiarity cuts incident response times by half while slashing training expenses.

Organizations leveraging predictive maintenance spend 8-12% less on emergency repair costs and 40% less than reactive maintenance. Advanced monitoring eliminates reactive spending, transforming maintenance from cost center to strategic asset.

Sustainability By The Numbers

Extended lifecycles can also boost Environmental, Social, and Governance (ESG) scores. Reducing environmental waste, carbon emissions, and water usage through the very act of maintaining data center equipment and extending its lifespan is a win. This also attracts sustainable investment funds and enhances stakeholder value.

Using third party ITAD providers like Human-I-T to help manage the lifecycle of their equipment is an additional step in improving your data center’s environmental impact. It’s also a cost effective and safer way to remove equipment that has finally reached the end of its usefulness for your data center.

Each year of extended data center equipment operation saves the planet and your budget. Multiplied across data center infrastructure, the impact transforms corporate environmental profiles.

While traditional approaches suggest replacing hardware every three to five years, modern equipment can function effectively for a decade or more with proper maintenance.

By implementing strategic lifecycle management, your organization can reduce maintenance costs by 50-70%, eliminate unnecessary upgrades, and contribute to critical sustainability goals. The choice isn’t between performance and sustainability – it’s about maximizing both.

The path forward requires more than just good intentions. It demands a partner with proven expertise in maximizing data center equipment value. Human-I-T’s ITAD experts can help identify which pieces of your infrastructure could benefit from professional renewal, upgrades, or secure data destruction and refurbishment. Ready to transform your approach to data center equipment? Fill out the form below to start your journey toward sustainable, cost-effective IT operations.